When DC voltage is applied to the input of an energy storage inverter, large inrush currents will occur as the DC bus capacitance will initially appear as a short. Without the use of a pre-charge unit, these inrush currents can damage the batteries, the capacitors and IGBTs.

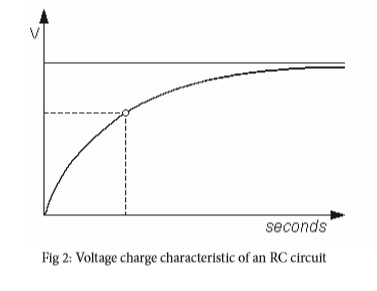

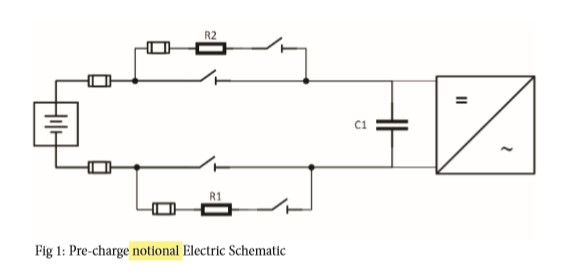

Essentially, a pre-charge circuit puts resistance in series with the bus capacitor. This increases the RC time constant of the bus capacitance circuit and slowly charges the bus capacitance, while dramatically reducing the peak current. The series resistance is then removed from the circuit to ensure that the decoupling capacitor can filter out the switching operations.

PV Inverter Pre-Charge Requirements

In most PV applications, pre-charge of the Inverter DC bus capacitance is not required due to the I-V characteristic of the PV cell. The inherent current limit of the PV array will limit the current inrush on the inverter bus to acceptable levels.

Battery Inverter Pre-charge Requirements

Batteries have extremely high short circuit capacities. This results in them being able to provide an extremely high peak inrush current to the inverter DC bus. This inrush current needs to be mitigated with the use of DC pre-charge assemblies.

Integrated DC Pre-Charge

Dynapower’s CPS and DPS product lines come with integrated pre-charge units. This equipment contains all needed components to safely and reliably pre-charge the DC link capacitance in the inverter.

Dynapower’s MPS product line does not come with an integrated DC pre-charge. These systems will need to be deployed with an external pre-charge assembly to safely and reliably start the inverter.

Go here to learn more about Dynapower’s energy storage solutions!