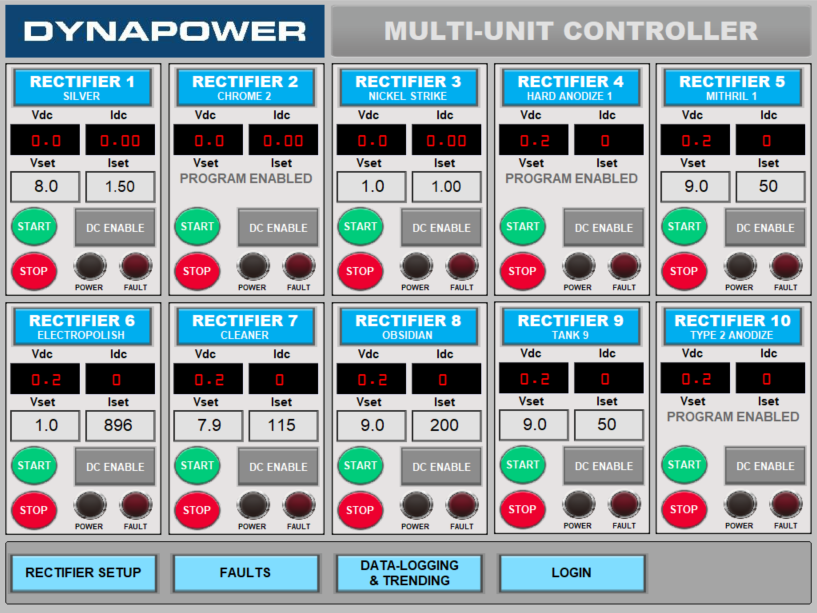

Multi-Unit Controller

Control up to ten units with one interface

Find out more.

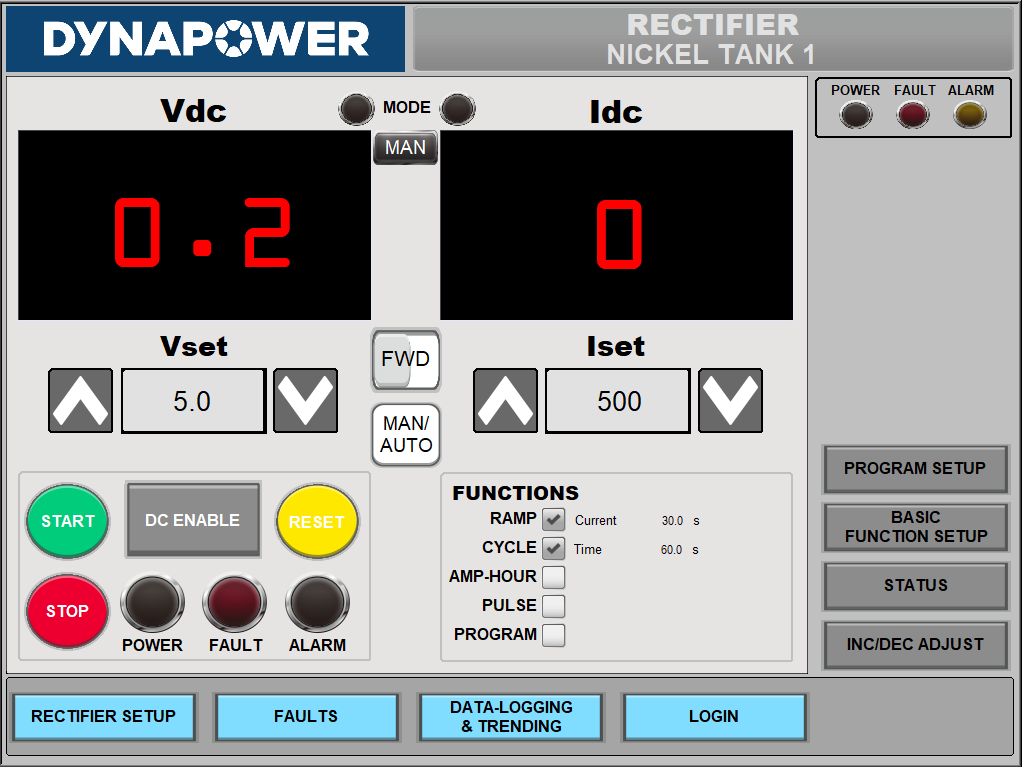

Our Multi-Unit Rectifier Controller offers convenience and efficiency by controlling multiple rectifiers from a single user-friendly touchscreen that can be centrally located in any facility.

Compatible with both SCR and switchmode rectifiers — which may include a combination of up to 10 power supplies of varying sizes — this controller saves valuable time with the automation of recipes, fault diagnostics, and data logging of all connected rectifiers from a central control interface.

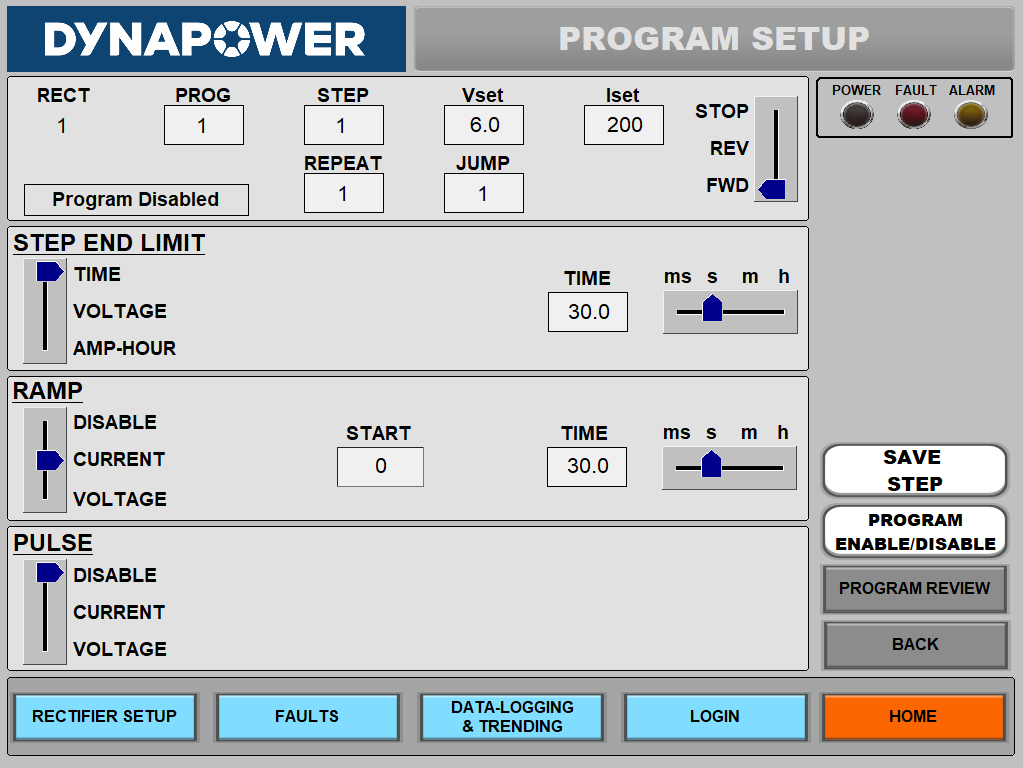

With the Multi-Unit Controller, you can create and store up to 12 custom recipes to suit any process, ensuring your process is completed the same way every time. Recipe steps include ramp, dwell, pulse, amp-hour, and cycle functions.

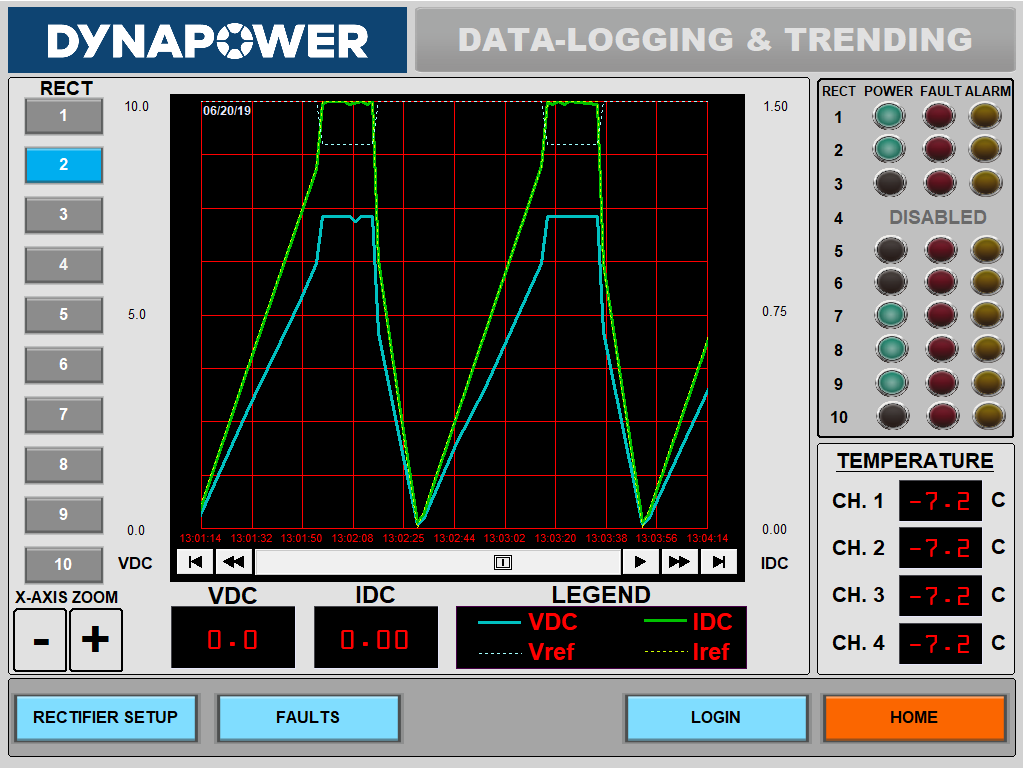

To ensure all audit requirements are satisfied, the Multi-Unit Rectifier Controller features data logging for objective evidence. The data logging feature saves detailed DC voltage and current feedback & setpoint data and reports upon the completion of every successful finishing cycle. All history is easily accessible for download and review for record keeping.

This controller features an intuitive touchscreen display built into a standard remote console, allowing for flexible controller placement. Custom control placement options are available on request. It can also be retrofitted to existing Dynapower rectifiers to modernize the control of your power supplies.

Features

- 12.1” Touchscreen interface (1024 x 768) for easy control

- Graphic display for viewing unit output, set-point reference levels, status indication, setup, and special operating modes

- Voltage and Current set-point adjust

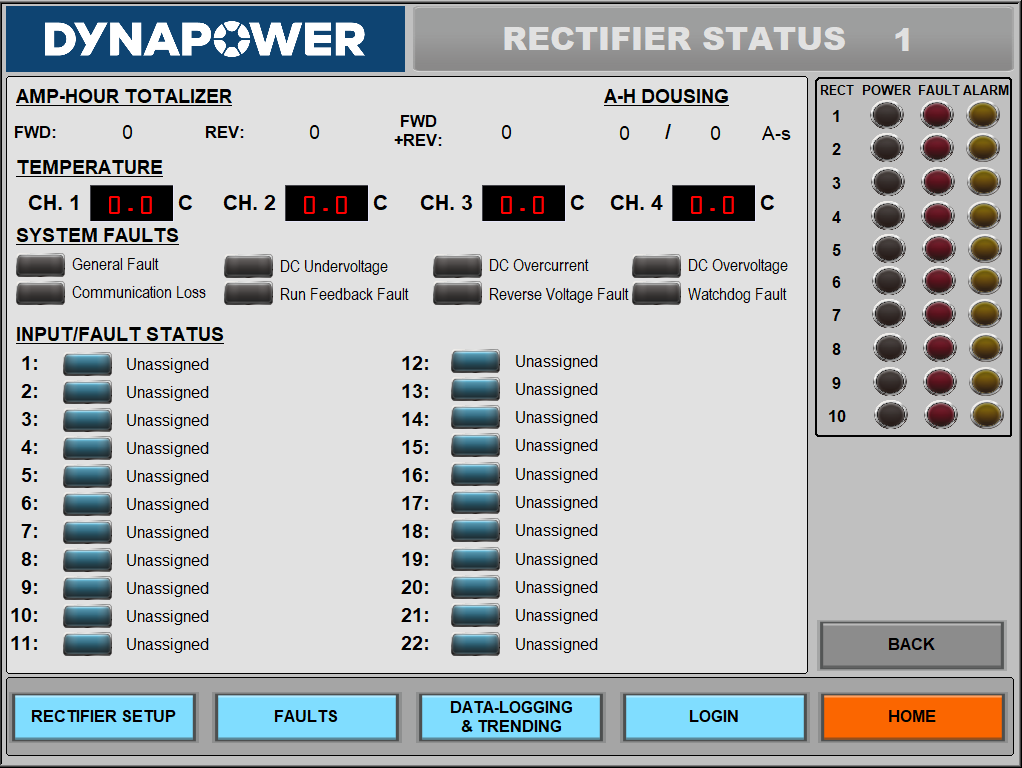

- Amp-hour totalizer with 9-digit resolution

- Amp-hour count dousing cycle. Can program digital output to change state after ‘X’ Amp hours is reached and program output to stay energized for ‘t’ seconds.

- Status screen showing all input and fault states

- In depth active fault and history reports to quickly identify and diagnose faults

- DC voltage and current feedback and setpoint trend display with cycle-based data logging

- Polarity reversal function (when applicable rectifier hardware present)

- Selection for customer remote interface (AUTO MODE) via Ethernet TCP/IP, Modbus TCP or Remote Analog (4-20mA/0-10VDC)

- Temperature monitoring readback/fault capability (Contact Dynapower for more information on hardware requirements)

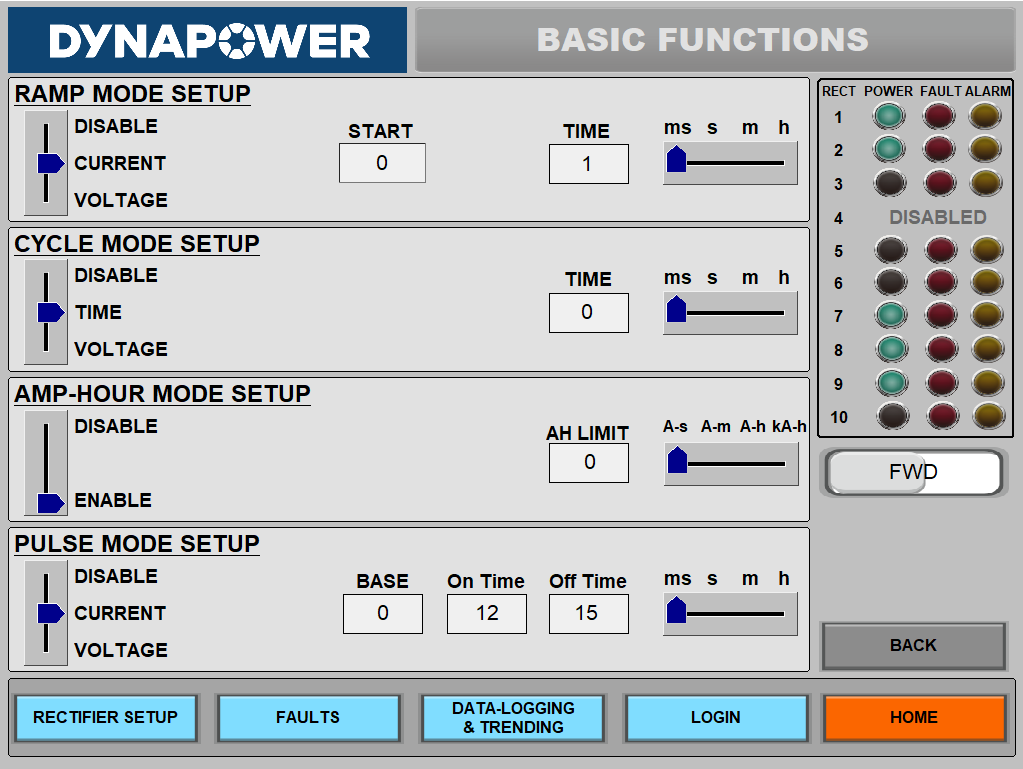

Basic Functions

- Ramp rate set-point adjust for both voltage and current modes

- Amp-hour cycle-limit adjust

- Pulse set-point adjust for both voltage and current modes

- End of cycle indication

- Cycle timer/voltage cycle limit adjust

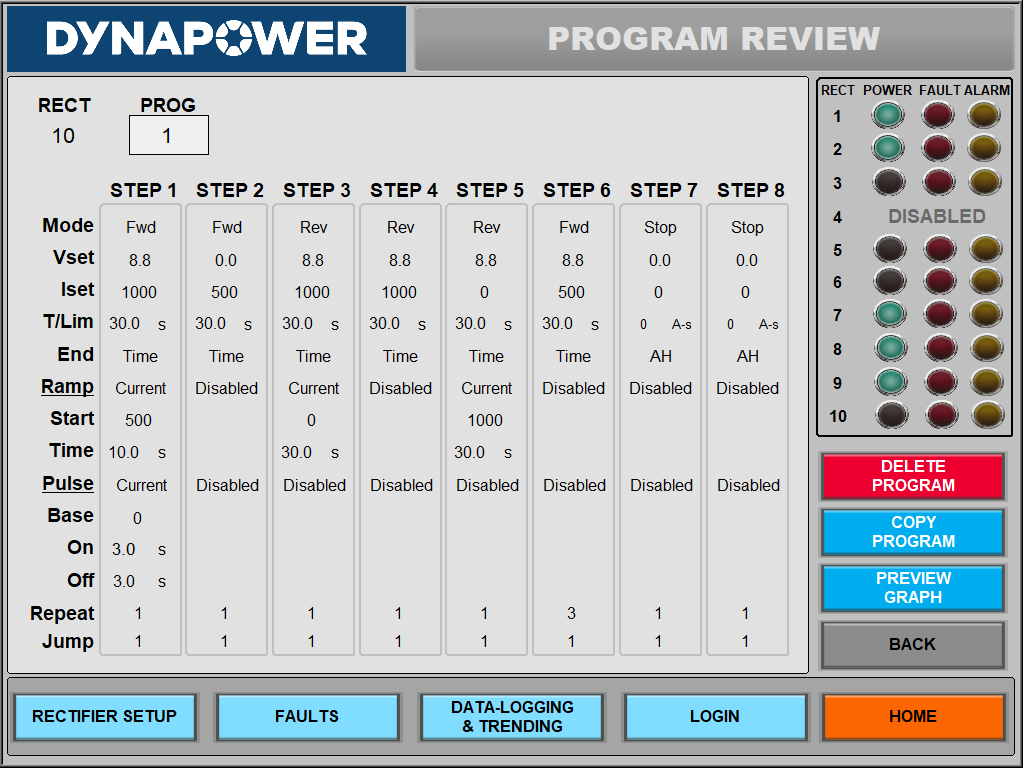

Program Functions

- Store up to 12 multi-step programs per rectifier

- Each program contains up to 8 steps that include ramp, dwell, pulse, amp-hour, and cycle functions, step repeat/jump functions

- Selectable time-base of milliseconds, seconds, minutes, or hours for all timers

- Intuitive and visual interface to set up and review programs

- Step repeat/jump parameters to allow for complex waveforms

- Ability to copy and delete full programs

- Programs and set-points automatically restored upon power-up

- End of program indication

Multi-Unit Controller Video

Discover what Dynapower can do for you.

Call us at (802) 860-7200 or fill out our form to schedule an appointment with us today.