At Dynapower, we refer to engineering upgrades as a term used to describe putting a non-original part in a machine as opposed to a repair—which refers to a like part for a like part exchange. An easy way to understand this is if you blow out your tire and replace it with the exact same tire it’s a repair whereas purchasing a higher end tire would be an upgrade.

Our main goal when considering engineering upgrades is determining how we can bring your piece of equipment that you know and love and are comfortable troubleshooting to the next level. When it comes to meeting today’s demand and production requirements, engineering upgrades to existing rectifiers are a great solution for a lot of customers.

Perhaps the most common engineering upgrade involves the installation of updated safeties. Every few years, laws and safety requirements are changed and updated. For instance, the NFPA70e requirement for emergency stops—which prohibits the use of guards around emergency stops—will require many customers to secure engineering upgrades in order to bring their equipment into compliance.

Another form of engineering upgrades around safety involves maintenance work. For instance, when your company requires employees to do maintenance work on your rectifiers or power supply, is the equipment safe to calibrate and do preventative maintenance work on? Do you need to change the electrical infrastructure to accommodate human beings performing mandatory tasks in or around the equipment?

At Dynapower, we’ve seen it all in our 50-plus years in the power supply business. We are adept at producing purpose-built solutions that meet YOUR specific requirements. For instance, here’s a small sampling of engineering upgrades we’ve implemented for our customers: extra thermal sensors, water pressure check valves, fan sensors, flow sensors, chemical contamination sensors and much more.

“We like to see the equipment and identify solutions such as if a door panel were to break/open the unit can be instantly de-energized,” according to Dynapower’s Repairs Supervisor Remington Schieffer. “We fix this by tying in external controls like moisture sensors or laser curtains so if something breaks that beam it sets off an alarm or shuts the whole system down.”

Ultimately, by knowing your process and learning about the liabilities in your facility, we can incorporate productive safeguards to accommodate your ever-growing workforce.

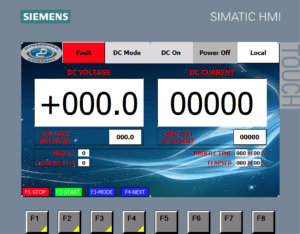

Dynapower’s Touchpad Controller

The next engineering upgrade to consider closely is ramping up your functionality. This can be done through cycling and custom programming—all of which come standard with our Touchpad Controller.

Our Touchpad Controller can be easily integrated into both silicon controlled rectifiers and switchmode power supplies. With our easy-to-use display, you can view controller setup, status indications and access special operating modes with ease.

Our Touchpad Controllers can be easily retrofitted to any existing Dynapower power supply or SCR units supplied from other manufacturers. These controllers give you the ability to make precise voltage adjustments, pulse duration, cycle time and dwell time.

“Back in the day when anodizing, operators would stand there during the whole anodizing process and turn the dial up little by little and watch the bath and turn the potentiometer up,” Schieffer elucidates. “And then the next best thing was little relays ramp cards that timed for you. Now we have the touchpad controller, which brings efficiency to a process and helps reduce defects by reducing mistakes.”

Dynapower’s Touchscreen & Multi-Unit Controllers

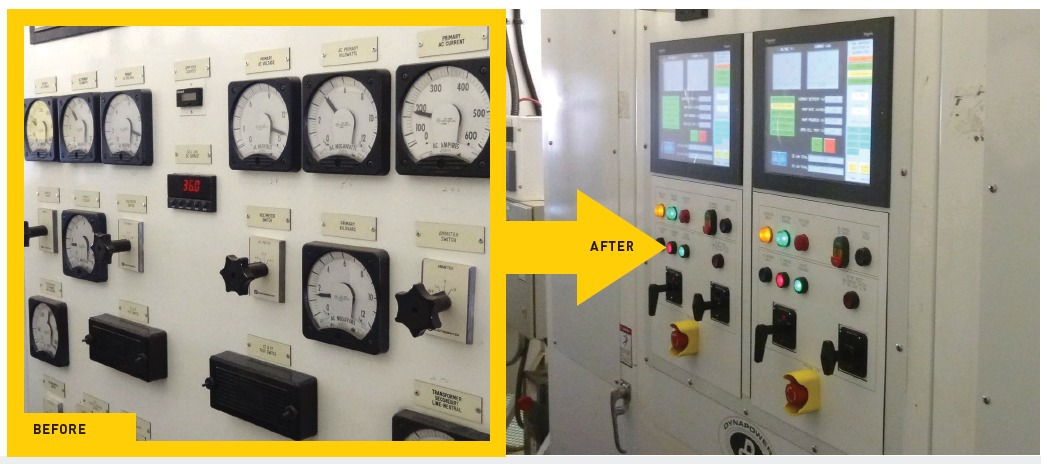

If you’re looking for the absolute best in terms of engineering upgrades then look no further than our Touchscreen Controllers and our brand new Multi-Unit Rectifier Controller. These devices are easily integrated into SCR rectifiers and offer users the ultimate control over their power supplies.

The Multi-Unit Rectifier Controller actually works with both SCR and SMPS units and can control between one and ten rectifiers from a single user-friendly touchscreen. This powerful controller also features a data logging system that allows you easily accessible downloads and record keeping.

Dynapower’s Multi-Unit Rectifier Controller allows users to save time with the automation of recipes, fault diagnostics, and data logging of multiple rectifiers from a single touchscreen.

“What we’ve done is we created a touchscreen interface designed to control multiple units instead of just one,” Scheiffer points out. “With these controllers, you can quickly unlock the potential of what you have. We’re able to take old rectifiers that have analog controls and easily upgrade them to the touchpad or touchscreen controllers.”

Both the multi-unit and touchscreen controllers boast graphic displays that feature easy to navigate menus which allow you to change options and make specific adjustments in just a few taps. Perhaps the most popular feature of our Touchscreen Controller is “profile mode.”

When running this mode, the controller can be used to create, store and use custom recipes with multiple steps. These steps include ramp, dwell, pulse, amp-hour, and cycle functions. Concurrently running operating modes allow for even more complex waveforms.

“If you can dream it, we can do it,” Scheiffer adds. “We build everything in house right here and are proud to produce purpose driven equipment.”

Just like our Touchpad Controller, the Touchscreen Controller can also be easily retrofitted to any existing Dynapower power supply or SCR units supplied from other manufacturers.

We hope this breakdown has given you insight into Dynapower’s engineering upgrades and solutions. We are excited to bring our Multi-Unit Rectifier Controller to market and look forward to continuing to uphold our reputation as a time-tested leader in the power supply industry.

“If you can dream it, we can do it,” Scheiffer adds. “We build everything in house right here and are proud to produce purpose driven equipment.”