In a nondescript building adjacent to the Burlington International Airport and minutes away from Dynapower’s manufacturing facility in South Burlington, Vermont, a quiet aviation revolution is underway. Kyle Clark and his team at Beta Technologies are fast at work developing a battery-powered electric airplane that could revolutionize global aviation and personal transportation.

Dynapower is helping power that revolution with its energy storage power electronics .

Battery-Powered Airplanes

Electric battery-powered airplanes are widely viewed as the next great leap in aviation technology. They burn no fuel and more importantly emit no emissions. In the past 150 years, carbon dioxide levels have risen 35%, and aviation has heavily contributed to that rise. A single person traveling on a roundtrip flight from New York to London generates the same greenhouse gas emissions as heating a single residential home for a year. 3 billion people fly annually. The International Civil Aviation Organization estimates that by 2050, aircraft generated emissions will triple in volume. Clark and his team at Beta could help change that course.

“I’d like to take that 9 percent of carbon emissions that are produced by aircraft and make that zero,” Clark said in an interview with VT Digger . “I’ve got four little kids; I really don’t want to destroy this world.”

Beta is not alone in its chase to fully electrify aviation. Google, Uber, Boeing, Airbus, and Raytheon are all developing fully electric battery-powered airplanes. While many of them are still in the theoretical stage or in non-manned flights, the AVA XC, Beta’s first iteration of its plane, has been flown by Clark dozens of times both in Burlington (KBTV) and Plattsburgh, New York (KPBG).

AVA’s Advanced Capabilities

Unlike traditional planes, AVA has the capability to vertically land and takeoff. Its magnetic rotors rotate to propel the 4,000 lb aircraft up, down and forward. The plane built mostly of carbon has two redundant battery packs totaling 124kWh. “We built AVA as much to learn as anything,” says Clark, whose team have been designing, building, and testing at a breakneck pace over the last twenty-four months.

Under construction now in Beta’s company’s workshop is a craft that will be twice the size AVA and able to go twice the distance. It will have a wingspan of under 50 feet and will be able to fly 290 miles before recharging. Clark expects the eventual commercial version to cost the same as a conventional six-seat propeller plane — $1 million. Beta’s planes are being built to transport cargo first, and then passengers.

At Beta’s office, engineers — some of whom have worked for the likes of GE and Twitter — design behind laptops around a communal table. 3D printers hum feet away generating prototype parts and airplane models. Across the room test pilots and computer programmers run simulations of the aircraft in development. A separate Beta facility mills parts and prototypes carbon propellers.

Flying Cross Country

Clark and the Beta team are preparing to fly AVA across the country this summer. A monumental task of coordination and aviation that doesn’t phase Clark. The lofty goal for the plane and Beta’s client whose funding much of the project is to create an electric battery-powered plane that will spirit human organs across the country for emergency transplants as part of a nationwide network of hospitals. Clark points to a map of over a dozen hospitals who’ve signed up already up and down the east coast.

Plane Charging Stations with Dynapower

In order to achieve the long term aims of the project, Clark and his team must not only develop the battery-powered electric plane and meet rigorous FAA safety standards in doing so, but they must also develop a charging station to charge and recharge the planes’ batteries. “It is here where Dynapower is providing critical support in both supplying equipment and expertise,” says Clark, a former Dynapower electrical engineer himself.

Dynapower is supplying Beta with DC/DC converters and energy storage inverters as part of Beta’s charging station. The Beta collaboration is a project near and dear to Dynapower’s Director of Energy Storage Chip Palombini. “Being a pilot myself, it is incredible to see the strides Beta has made in such a short period of time,” says Palombini.

Clark and the Beta team have built a mobile charging station in a former tour bus to power AVA’s charging. The bus is outfitted with Dynapower power electronics, and expandable roof for AVA to land on. While at the other end of the airport a team is building a prototype of the permanent charging station — the first of which will be deployed outside Beta’s offices in South Burlington a short distance away from the public air terminal.

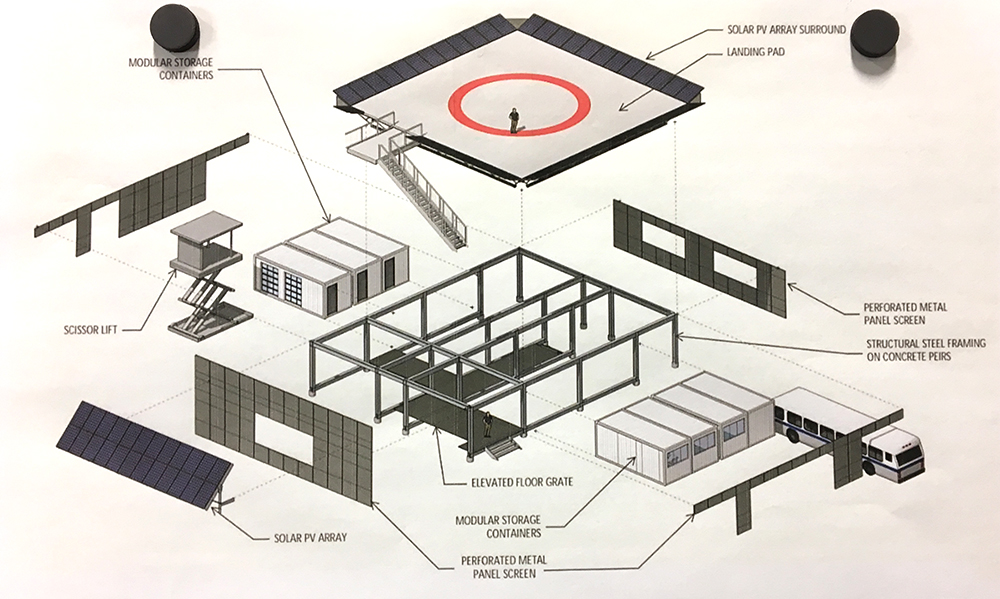

Each charging station is constructed of a group of shipping containers. A landing pad spans several containers which will house everything from the actual charging station itself complete with batteries and Dynapower power electronics to quarters for the pilots to rest as required by FAA rules, and facilities for small airplane repairs. The modular structure assembles much like an erector set and is designed to be easily be transported by tractor-trailer without special permits.

“The stations can be grid-tied, tied to solar or wind and operated as a microgrid, or both,” says Clark, noting that when the stations are not in use the stored energy could be sold and fed into the local grid to offset expenses of operating the station and the planes. “Dynapower’s power electronics help provide us with that flexibility.”

Christian Bailey, a pilot who co-founded a venture fund called Curated Innovation in Cambridge, Massachusetts told VT Digger that Beta is unique among eVTOL startups with its goal for long-range flight.

“I was kind of stunned to see those shipping container battery packs (and power electronics),” said Bailey, who visited Clark’s company in November. “They can drop those things across the U.S. and allow one of these crafts to cross the whole country without ever needing to go to an existing (base), and certainly nobody else in the space is doing that.”