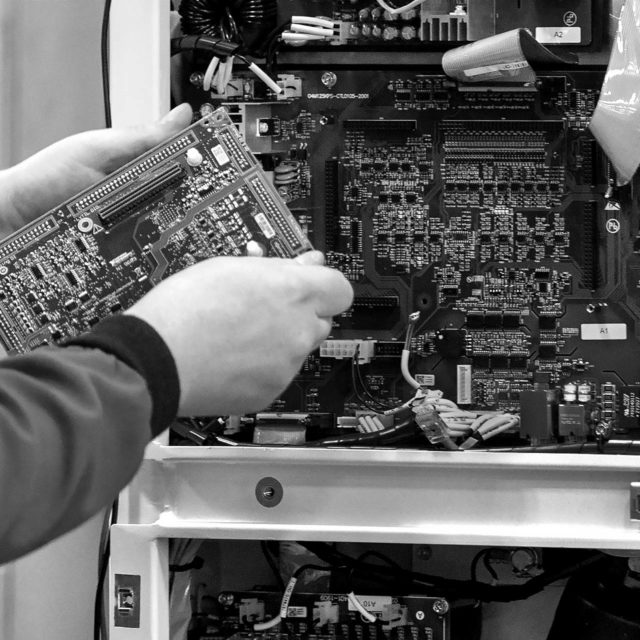

Preventative Maintenance

Ensure maximum equipment uptime and performance.

When you’re protected with a Preventative Maintenance Plan, you have the peace of mind that comes with knowing your systems are well-maintained and in compliance with industry standards. Your equipment is inspected and adjusted on a regular basis, and its reliable operating life is extended — which helps to ensure the strength and sustainability of your business.

For technical assistance with your Dynapower equipment, please contact us:

PLAN options that work for you

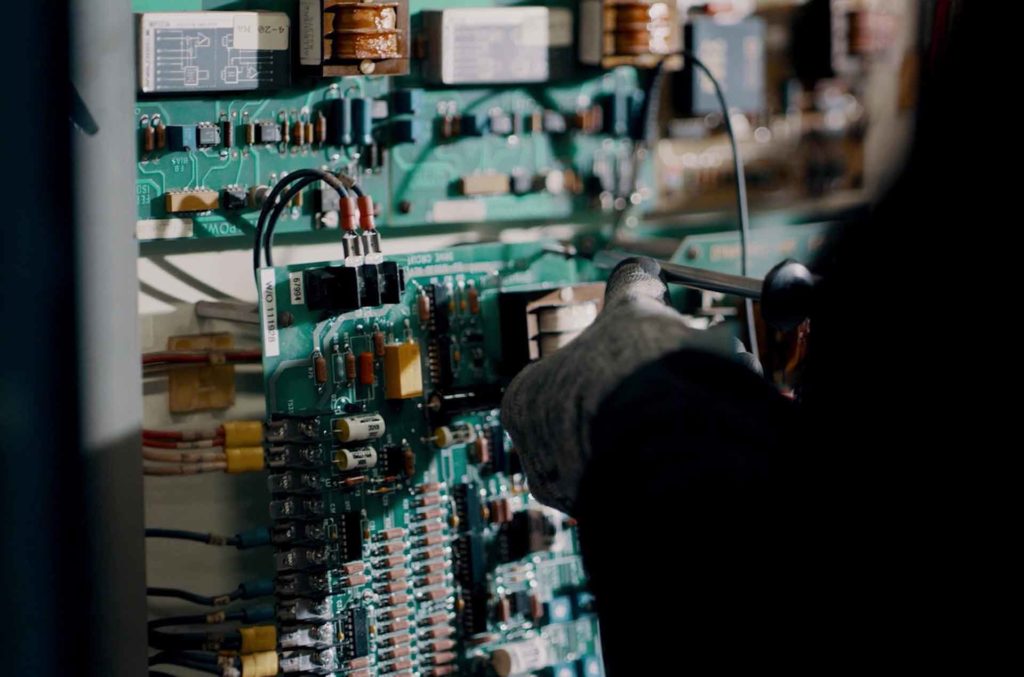

With a Preventative Maintenance Plan, a Dynapower factory-trained technician visits your facility at regular intervals and works with your maintenance team to ensure the ongoing reliability and performance of your equipment. Based on decades of service experience, our plans are available in 4 different service levels and cover a series of health, safety, performance, and compliance checks. They are designed to extend mean-time-between-failures, raise overall equipment effectiveness, and allow your production to stay on schedule.

all makes and models

Our plans cover all rectifiers, converters, and transformers — not just Dynapower and Rapid brands, but those of any manufacturer.

Process know-how

At Dynapower, we don’t just know the equipment. We understand the processes they power. We service a wide range of industries — including energy, defense, and manufacturing — that rely on us to keep their power conversion and energy storage equipment running smoothly.

Plans that pay for themselves

Our Preventative Maintenance Plans pay for themselves over time, all while keeping processes running smoothly and safely. For a fleet of equipment, preventative maintenance is literally pennies on the dollar compared to the cost of downtime or equipment failures.

Dynapower Preventative Maintenance Plans

| Bronze | Silver | Gold | Platinum | |

|---|---|---|---|---|

| Qualitative report on Rectifier state of health A detailed report of the health and safety of each rectifier |  |  |  |  |

| Calibration Verification Confirm rectifier controls and meters are accurate |  |  |  |  |

| Safety Check Confirm all rectifier safety equipment is operational and functioning properly |  |  |  |  |

| Total yearly service visits Number of visits based on MIL-SPEC, NADCAP, and IATF industry standards | 1-4 | 2 or 4 | 2 or 4 | Custom |

| Required Maintenance Downtime Required downtime to complete service and inspection |  | Once per year | Once per year | Negotiated |

| Priority Scheduling | >Non PMs <Emergencies |  |  |  |

| Testing Portal Installed Required installation of equipment to complete live testing |  |  |  | |

| Rectifier Assessment Dashboard A single page visual representation of the health and safety of each rectifier |  |  |  | |

| On Site Technician Training Live training for facility maintenance employees during service visit |  |  |  | |

| Industry Compliance Certificate Third party verification of the consistency and accuracy of rectificatio process. Certificates are compliant to the standards ofNADCAP, IATF, MIL-SPEC, and other major manufacturer technical compliance standards. |  |  | ||

| Tracking Electrical Performance Measure electricity to the busing to the part being finished and back to the rectifier to confirm connection efficiency. |  |  | ||

| Individual Performance Tolerance Confirm rectifier is performing during process to allowable tolerances. |  |  | ||

| Metrology Verification of Meters Verification and visual certification of meter accuracy. |  |  | ||

| Preferred AMS Pricing Repairs, Engineered Upgrades, Refurbishments | Available | |||

| Spare Parts Included | Available | |||

| Emergency Visits | Available | |||

| Guaranteed Uptime | Available | |||

| Guaranteed Response Time | Available | |||

| Custom Training Developed on Specific Customer Power Supplies | Available | |||

Power ahead with us

Interested in knowing more about services and support at Dynapower? Call the Dynapower Service Hotline at 1 (800) 332-1111 or click the link below to reach out to us. We look forward to hearing from you.